Project Description

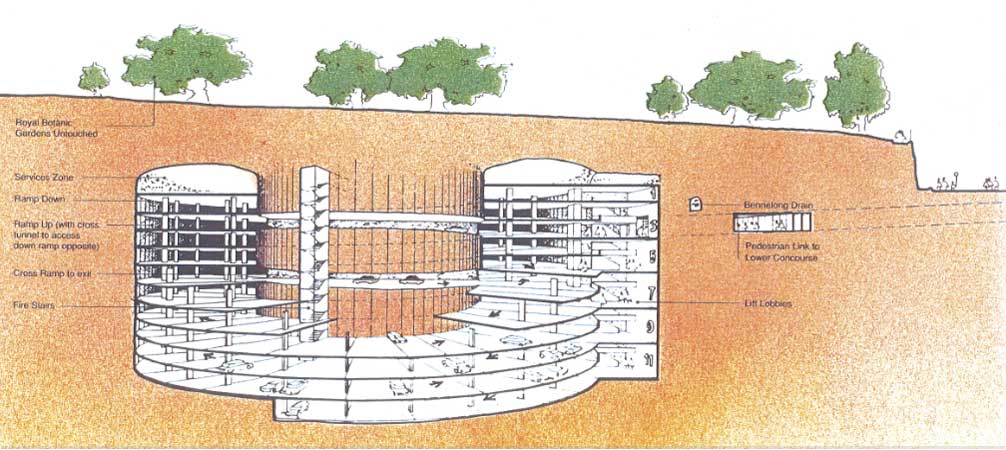

The underground car park for Sydney Opera House with a capacity of 1,100 cars was officially opened by NSW Premier and Treasurer John Fahey on 17th March 1993, at a cost exceeding $40 million. The Sydney Opera House car park, known as the Bennelong Point Parking Station, is unique in shape and size and has established a number of firsts during its construction.

It is the first helical underground parking station tunnels with a huge doughnut-shaped cavern, with a span of up to 19 m and an outer radius of 75 m, contains a 12 story free-standing double-helix concrete structure which, while providing 1100 parking spaces It is possibly the widest shallow-cover rock cavern in the world. The roof spans between 17.5 m and 19 m and comprises between 7 m and 8 m of variably weathered Hawkesbury sandstone, a rock which ranges in strength from 15MPa to about 40 MPa.

The roof is the key feature of the cavern. It is not supported with a formed concrete arch but rather, internal reinforcement comprising tensioned Macalloy bar anchors up to 7.5 m long and untensioned galvanised dowels up to 4.5 m long. There are about 2000 anchors and dowels in the roof. Design of the reinforcement system involved the development of a new design method which is described in a paper presented at the 7th ISRM Congress, Aachen, 1991.

The impor¬tant design features of the roof are:

• the roof is almost flat, as this is found from both analytical studies and experience to be appropriate in horizontally bedded strata with a relatively high horizontal stress field

• the capacities and distribution of the rein¬forcing elements were designed so as to tie together the horizontal beds of sandstone (ranging in thickness from 1 m to 3 m) to act as a single pseudo-elastic no-tension linear arch.

• the roof surface is covered with a 150 mm skin of reinforced shotcrete and fibrecrete which acts as a membrane between the reinforcing elements.

Other special challenges in this project were:

• portions of the underground excavations are beneath outbuildings of Government House.

• the cavern is within 60 m of Sydney Harbour and extends 28 m below sea level.

• all work had to be done without disrupting the surface other than for the two 9 m wide access which have to pass over the Sydney Harbour Tunnel and have, in places, rock cover as low as 2.5m.

In addition to the main cavern, 16 tunnels had to be excavated ranging in span from 2 m to 12 m.

Excavation of the access tunnels and the crown section of the main cavern was achieved primarily by a Mitsui S200 roadheader. This machine proved to be the first roadheader which could cut the high silica content Hawkesbury Sandstone (75% to 85% silt and sand size quartz) with both reasonable productivity and pick-wear rate. Attempts were made to use an AM65 in parallel with the Mitsui but, as in previous Sydney tunnelling projects, pick-wear rates were unacceptably high. A second S200 machine was brought onto the site and a small S65 machine was also used for a 1.6 m wide tunnel required for diversion of an old stormwater tunnel.

The crown section of the main cav¬ern was excavated by successive widen¬ing from an initial outer 6 m wide heading. Support was installed as the heading was widened from 6 m to 10 m to 15 m to 18 m. Careful monitoring of roof deflections, rock anchor loads and roof delamination was undertaken as the span increased, as a check against design assumptions. Once the crown was fully excavated and sup-ported, a D10 bulldozer fitted with an impact ripper was used for bulk excava¬tion, this was probably the first underground use of a Caterpillar D10 with an impact ripper. The cavern walls were trimmed by two Kato HD 1250 30 tonne excavators and one Kato HD900 fitted with Montabert hydraulic impact breakers. These were also used to cut slots up the cavern walls for ventilation risers and for excavation of the lift shaft.

Instrumentation of the cavern included:

• multipoint extensometers installed from the ground surface prior to cavern excavation

• inclinometers installed around the perimeter and in the core prior to excavation

• sag measurement points on the cavern roof

• a subsidence grid on the ground above the cavern

• a piezometer network

Main cavern design calculations predicted roof sag of about 15mm at full span and also settle¬ment above the core of about 8mm. Monitoring showed that the roof rock deflected as a unit, with surface settlements being only a few millimetres less than internally measured roof sag. Excavation of the cavern and associated tunnels, involving some 130,000 m3 of sandstone, started in late 1990 and was completed in April 1992. The twelve story concrete helix was com¬pleted in September 1992 and the parking station is expected to open March 17, 1993, six months ahead of schedule